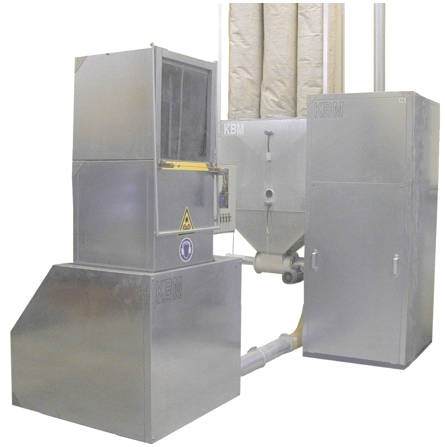

A complete recycling system

The KBM MAXI recycling plant consists of one combined pre-crushing and granulating unit, and a separate dust separating unit - both units are sound insulated. After the recycling, the material is blown into a storage silo made from plastic fabric, sewn as one big bag with steel frame for easy assembling.

Thanks to the two step/double chamber system and the large sieve surface and granulation chamber the MAXI Recycling plant produces a high quality recycled material which contains a minimum of dust from waste production, cut-offs from block production or even from used EPS and EPP/EPE mouldings.

The MAXI recycling unit breaks down the material to individual beads homogeneous with new pre-expanded beads. This consequently results in minimization of uneven density distribution caused by de-mixing problems. Blocking of core vents due to dust and lumps of material causing hot wire cutting problems in terms of inaccurate sheets with bad surface are also minimized.

The recycled EPS and EPP material can be reused in shape moulding production in a ratio of at least 10-20 percent without any perceptible optical or physical change of the product quality. For block moulding 20-50 percent can be added.

The KBM MAXI recycling plant for EPS and EPP is suitable for large shape moulding and block moulding operations.

Extensions for your MAXI unit

As an extension to the MAXI Recycling plant, we offer metering/mixing systems compatible with the unit. All units can be delivered separately.

- For shape moulding production, we offer two metering/mixing systems. The metering unit is steplessly variable to ensure correct metering of EPS before the pre-expander and of EPP before the pre-pressurizing tank. The KBM Styromix units are available to give an individual and exact mixing of material for each moulding machine.

- For block production, Styrometer with two silos and metering/mixing station, to be placed just before the block mould, is available. In the same way it can be used to fill pre-pressurizing tanks with recycled and new EPP material mixed in an accurate ratio.

Read more about the KBM metering/mixing systems here.

For small size shape moulding operations the MINI recycling plant is available, just like our JUMBO recycling plant is available for very large shape and block moulding operations.